Become a skilled welder and fabricator with our intensive 800-hour program!

800-Hour Comprehensive Welding Program

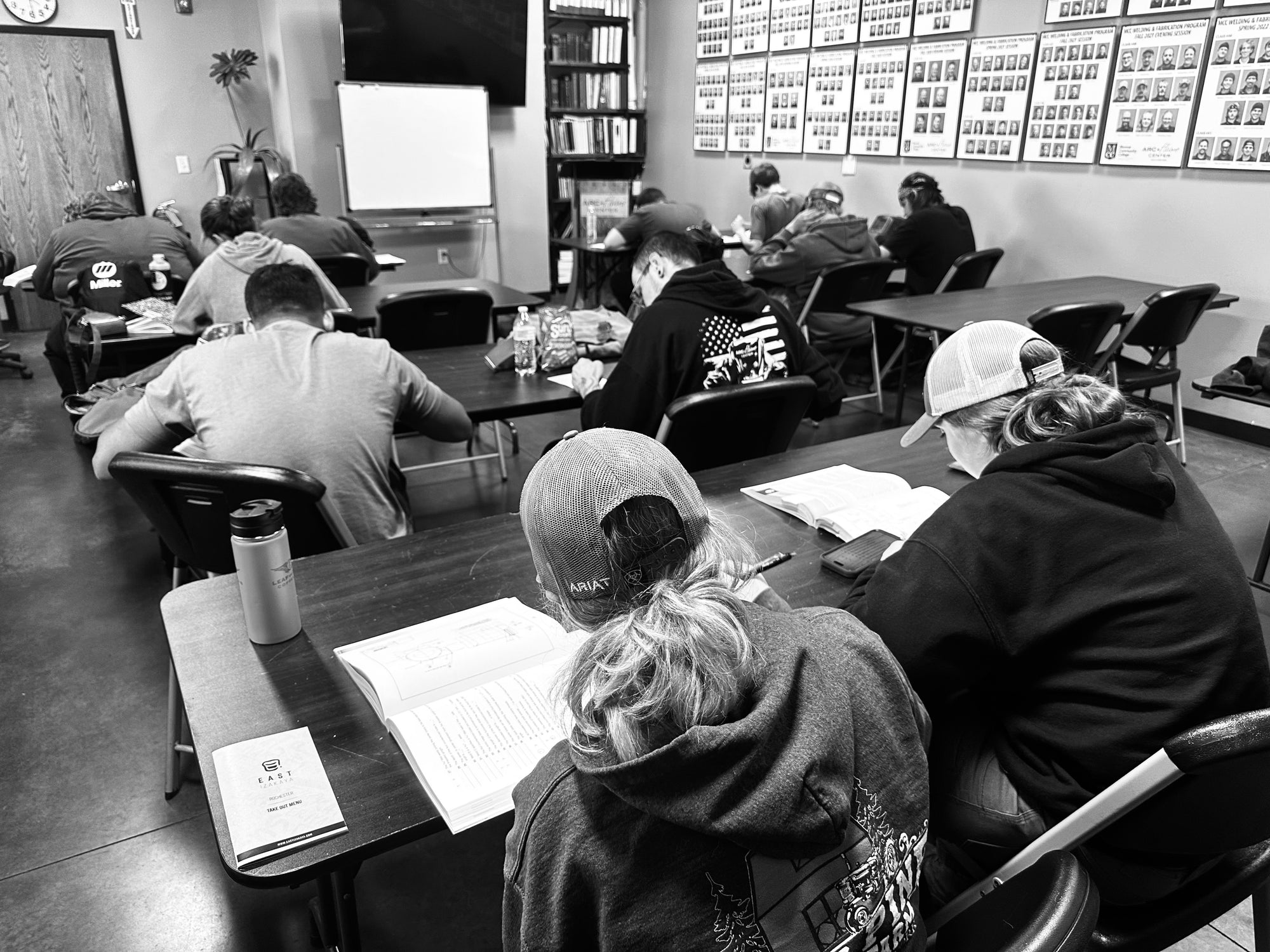

At Forged by Valor, we equip Veterans and individuals seeking career transitions with the technical skills and industry knowledge needed to thrive in the rewarding field of welding and fabrication. Our comprehensive program provides a strong foundation in various welding processes, blueprint reading, fabrication techniques, and essential industry knowledge.

100% Tuition-Free Training

For Eligible Veterans

The full program tuition is FREE for eligible Veterans. This essential funding is generously provided by the Veterans Outreach Center.

For all other customers: The program tuition is $20,000.00, payable only upon acceptance of your application. This cost represents the full value of the program and covers the following comprehensive breakdown below.

Program Details

- Total Hours: 800 (250 Lecture, 550 Lab)

- Weeks: 20

- Days per Week: 5

- Hours per Day: 8 (Total) | 2-3 (Lecture) | 5+ (Lab)

- Start Time: 7:30 AM

- End Time: 4:30 PM

- Lunch Break: 12:00 PM - 1:00 PM

Cost: $20,000.00

- Academics: $550.00

- Tools & Equipment: $1000.00

- Welding Material: $2,500.00

- Consumables: $1,200.00

- Testing / NDT / NDE: $1,000.00

- Facility Rental: $3,000.00

- Instruction($13.44 per/hr.): $10,750

Semester based Schedule

The Forged by Valor program is a semester-based program that offers two start dates per year:

Spring Semester: February - June

Fall Semester: September - January

The program is designed to be completed in 20 weeks not including holidays

The Forged by Valor Welding & Fabrication Program equips you for success from the start.

Everything you need to launch your welding career is included in your program tuition, over $1,000 worth of industry-standard tools and equipment that you get to keep! This includes all safety gear, consumables, materials, learning resources, and testing. There are no hidden fees or surprise costs. The only exception is a pair of steel-toed shoes, which we recommend for your safety but are not included in the program.

Here's a breakdown of some of the valuable equipment you'll receive and use throughout the program, all of which becomes yours to keep upon graduation:

Here's a glimpse into your weekly journey:

- Explore Core Welding Processes: Gain a solid understanding of Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and safety protocols.

- GMAW Fundamentals: Delve into the science behind GMAW welding, including proper travel speed and amperage adjustments for optimal weld quality.

- Develop Blueprint Reading Skills: Learn to interpret blueprints and welding symbols essential for project execution, focusing on applications for GMAW projects.

- Hone Shop Math Skills: Master calculations crucial for electrode selection, joint preparation, and material thickness determination specific to GMAW.

- Introduction to Non-Destructive Testing (NDT): Gain insights into NDT methods used to inspect welds for quality assurance.

- Qualification Projects: Put your acquired skills to the test through practical GMAW and SMAW qualification projects.

- Advanced Techniques: Master advanced welding techniques for both GMAW and SMAW, enabling you to weld in various positions (flat, horizontal, vertical, overhead).

- Welding Procedure Specifications (WPS) & Codes: Understand the role of WPS and Welding Codes in ensuring consistent and high-quality welds in both GMAW and SMAW applications.

- Thermal Cutting Processes: Discover Plasma Arc Cutting and Oxy-Fuel Cutting and their applications in fabrication projects.

- Embrace Gas Tungsten Arc Welding (GTAW): Learn about GTAW equipment setup, proper torch manipulation, and arc control techniques.

- GTAW Electrodes & Technique: Explore proper selection and handling of various GTAW electrodes while developing your GTAW welding skills through hands-on practice.

- Focus on Advanced Transfer Methods: Delve into advanced metal transfer methods for GMAW Pulse and GTAW Pulse, expanding your skillset for greater control and weld quality.

- GTAW Qualification Project: Showcase your expertise in GTAW through a qualification project, solidifying your proficiency.

- Advanced Transfer Methods for Steel: Explore advanced techniques for welding steel, including spray transfer for GMAW and advanced pulse techniques for GTAW.

- Fabrication Principles: Learn about fabrication principles for various materials, including stainless steel and aluminum, focusing on reading plans, creating cut lists, and material estimation.

- Career Launch Support: Gear up for your welding career with resume writing, interview skills training, and job search strategies.

- Capstone Project: Undertake a comprehensive capstone project, applying your cumulative welding and fabrication skills to create a real-world project to help our veterans in the community.

- Graduation & Career Development: Celebrate your accomplishment at graduation! Receive guidance on career development and resources to help you launch your rewarding career in welding and fabrication.

Who We Are Looking For:

We are seeking highly motivated individuals with a strong desire to learn and a commitment to excellence. Ideal candidates will possess the following qualities:

- High School Diploma or GED (or equivalent): A foundation in core subjects like math and science is helpful.

- Trainability and Desire to Learn: A willingness to learn new skills and a strong work ethic are essential.

- Ability to Work Independently and as Part of a Team: Welding requires both independent focus and the ability to collaborate effectively.

- Good Dexterity and Hand-Eye Coordination: Precise control and coordination are crucial for successful welding.

- Problem-Solving Skills: The ability to identify and troubleshoot welding issues is essential.

- Basic Physical Fitness: Welding often involves lifting, carrying, and maneuvering equipment.

- Strong Work Ethic: Dedication and a commitment to excellence are key to success in the welding field.

Being a Veteran is a Plus:

We understand the unique skills and dedication Veterans bring to the workforce. Your experience in following instructions, working in teams, and solving problems under pressure can be valuable assets in the welding industry.

Desired Skills (may be beneficial but not required):

- Prior Welding Experience: Experience with welding processes like GMAW, GTAW, or SMAW can be advantageous.

- Basic Metalworking Knowledge: Understanding different metals and their properties is a plus.

- Blueprint Reading Skills: The ability to interpret blueprints and welding symbols is valuable in many welding jobs.

- OSHA Safety Certification: Possessing a valid OSHA safety certification demonstrates a commitment to workplace safety.

Ready to Forge Your Future in Welding?

Are you passionate about welding and ready to embark on a rewarding career path? We encourage you to apply! Veterans, we especially welcome your skills and experience in our program.